High-speed Machine Vision solutions for Industrial, Defence and Aerospace applications

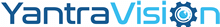

Founded in 2015, YantraVision is a high-speed Machine Vision product and solution company. Our Vision Processing Module, Falcon Compute, is a hardware platform (Embedded/Linux systems) bundled with algorithms. Falcon compute can be customized to build solutions for Industrial, Defence and Aerospace applications.

Falcon compute can be used along with Line scan camera, Area scan camera and SWIR camera with high-speed interfaces such as CameraLink, CoaXPress and GigE. The module uses high-speed FPGA for pixel level processing and GPU acceleration for image level processing.

Falcon compute has been used to build solutions like Print Quality Inspection system and High-speed Sorting Machine.

Products & Platforms

Falcon compute is a proprietary hardware platform bundled with algorithms and can be used to build high-speed solutions.

Solutions – Optical Sorting

High-speed optical sorting solutions for free-fall and conveyor based applications. Solutions built using FPGA systems.

Solutions – Print Inspection

High speed inspection solutions for print inspection and other web applications. Solutions built using GPU accelerators.

SWIR Solutions

SWIR solutions for applications unsolved using visible spectrum. Solutions like Fill Inspection, Fruit sorting & grading.

Products & Platforms

Falcon compute is a proprietary hardware platform bundled with algorithms and can be used to build high-speed solutions.

Solutions – Optical Sorting

High-speed optical sorting solutions for free-fall and conveyor based applications. Solutions built using FPGA systems.

Solutions – Print Inspection

High speed inspection solutions for print inspection and other web applications. Solutions built using GPU accelerators.

SWIR Solutions

SWIR solutions for applications unsolved using visible spectrum. Solutions like Fill Inspection, Fruit sorting & grading.

Products & Platforms

Falcon compute is a proprietary hardware platform bundled with algorithms and can be used to build high-speed solutions.

Solutions – Optical Sorting

High-speed optical sorting solutions for free-fall and conveyor based applications. Solutions built using FPGA systems.

Solutions – Print Inspection

High speed inspection solutions for print inspection and other web applications. Solutions built using GPU accelerators.

SWIR Solutions

SWIR solutions for applications unsolved using visible spectrum. Solutions like Fill Inspection, Fruit sorting & grading.

Design, Prototype, Develop, Deploy.

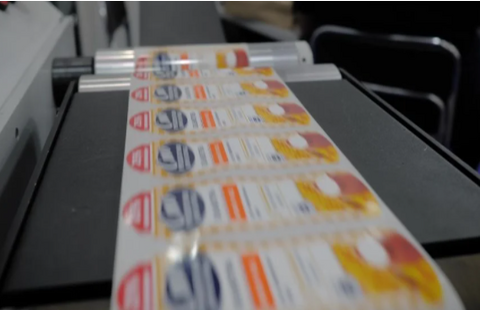

Print Quality Inspection Systems

Quality is paramount in the Printing industry especially if the product is used for packaging or labelling of pharmaceutical or other critical end products. Some of the defects that are common during the Printing process are registration errors, color variance, variable data defects, die-cut variance, streaks, smudges etc.

Falcon compute with GPU acceleration is used to build such solutions that detect defect sizes of 250 microns at a speed of 300 meters/minute. These solutions are capable of handling large horizontal dimensions.

Fill Inspection using SWIR Cameras

The FMCG, Beverage and Pharmaceutical industries have highly automated systems in their production line to fill containers and package them. The containers must all be filled to the same level to maintain high quality standards and protect brand reputation. The challenge is to identify and remove overfilled and underfilled containers without affecting the production output.

The SWIR based solutions can be used for Fill Inspection of different materials like liquid in a container, powder in a container and solid items like cookies, meat in plastic packaging. SWIR illumination penetrates plastic packaging and can be imaged using SWIR cameras.

Free-fall Optical Sorting for Food Sorting

The agricultural industry has strict quality control measures that are both self-imposed and government-mandated. Discoloured and broken grains, grains with mould or foreign matter, and grains that are severely misshapen can significantly lower the quality of the agricultural produce. The two-fold challenge is to ensure high-quality standards while maintaining high production throughput.

Optical sorting is done on conveyors or gravity feed (free-fall sorting), depending on the size of the raw material and the throughput required. Optical sorting machines for grains involves high-speed free-fall sorting process with hard real-time processing achieved in less than 2 milliseconds.

Print Inspection

Print Quality Inspection Systems

Quality is paramount in the Printing industry especially if the product is used for packaging or labelling of pharmaceutical or other critical end products. Some of the defects that are common during the Printing process are registration errors, color variance, variable data defects, die-cut variance, streaks, smudges etc.

Falcon compute with GPU acceleration is used to build such solutions that detect defect sizes of 250 microns at a speed of 300 meters/minute. These solutions are capable of handling large horizontal dimensions.

Fill Inspection

Fill Inspection using SWIR Cameras

The FMCG, Beverage and Pharmaceutical industries have highly automated systems in their production line to fill containers and package them. The containers must all be filled to the same level to maintain high quality standards and protect brand reputation. The challenge is to identify and remove overfilled and underfilled containers without affecting the production output.

The SWIR based solutions can be used for Fill Inspection of different materials like liquid in a container, powder in a container and solid items like cookies, meat in plastic packaging. SWIR illumination penetrates plastic packaging and can be imaged using SWIR cameras.

Free Fall Optical Sorting

Free-fall Optical Sorting for Food Sorting

The agricultural industry has strict quality control measures that are both self-imposed and government-mandated. Discoloured and broken grains, grains with mould or foreign matter, and grains that are severely misshapen can significantly lower the quality of the agricultural produce. The two-fold challenge is to ensure high-quality standards while maintaining high production throughput.

Optical sorting is done on conveyors or gravity feed (free-fall sorting), depending on the size of the raw material and the throughput required. Optical sorting machines for grains involves high-speed free-fall sorting process with hard real-time processing achieved in less than 2 milliseconds.

#Knowledgeseries

Subscribe to get regular updates on the latest and relevant trends in Machine Vision

#Discussion

Would you like to have a discussion on how Machine Vision will fit into your application?